- AM/NS India took the initiative to build India’s first all-steel slag road at Hazira under the technical guidance and supervision of senior scientists from CSIR – Central Road Research Institute

- We are confident that steel slag will become a popular raw material in road construction in the coming years: Dr Anil Matoo, Head HR Operations, IR, and Administration at AM/NS India.

- In June, AM/NS India won the order for the supply of 1 lakh tonnes of steel slag for the construction of a 36.93 km eight-lane stretch from Ena to Kim in Surat as a part of the upcoming Vadodara-Mumbai Expressway.

NE BUSINESS BUREAU

HAZIRA-SURAT, JULY 16

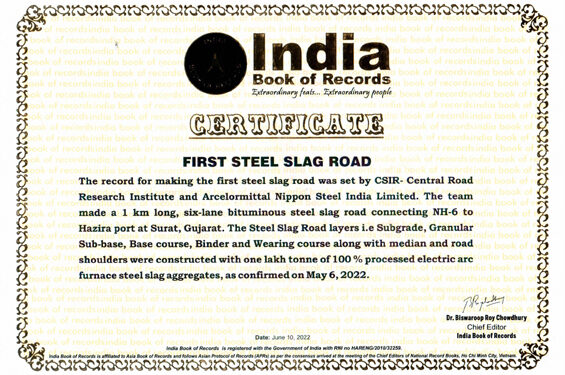

ArcelorMittal Nippon Steel (AM/NS India), a joint venture between Arcelor Mittal and Nippon Steel, on Saturday announced that it has found a place in the prestigious India Book of Records for building the country’s first steel slag road.

We're delighted as the Hon'ble Union Minister of Steel, @RCP_Singh, inaugurates the country's first #SteelSlagRoad in Surat, Gujarat – developed by @AMNSIndia, in association with @CSIRCRRI and @NITIAayog.@PMOIndia@narendramodi@SteelMinIndia@CMOGuj#SmarterSteelsBetterWorld https://t.co/iEK1uERjGZ

— ArcelorMittal Nippon Steel India (@AMNSIndia) June 15, 2022

“The record for making the first steel slag road was set by CSIR – Central Road Research Institute and ArcelorMittal Nippon Steel India. The steel slag road layers, i.e. subgrade, granular sub-base, base course, binder, and wearing course along with median and shoulders were constructed with one lakh tonnes of 100% processed electric arc furnace steel slag aggregates,” India Book of Records said in its official record noting.

In collaboration with @GRInfraprojects, we supplied Steel Slag for @NHAI_Official Vadodara-Mumbai Expressway. @AMNSIndia is a forerunner in the #SteelSlagRoad technology, an environment-friendly, cost-effective alternative to road construction materials.#SmarterSteelsBetterWorld pic.twitter.com/qL5sS2PTtu

— ArcelorMittal Nippon Steel India (@AMNSIndia) June 15, 2022

A byproduct obtained during the primary steel manufacturing process, steel slag is known to be an environment-friendly and cost-effective alternative to natural aggregates used in road construction. AM/NS India’s Hazira integrated steel manufacturing facility at Hazira generates around 2 million tonnes of steel slag a year.

AM/NS India took the initiative to build India’s first all-steel slag road at Hazira under the technical guidance and supervision of senior scientists from CSIR – Central Road Research Institute. The 1.2 km road, opened for traffic in May last year, is the country’s first road built using 100% processed steel slag aggregates. Around 1 lakh tonnes of steel slag was used in its construction. Daily, more than 1,200 heavy vehicles ply the road, which offers the same riding quality as national highways constructed using natural aggregates.

“AM/NS India is proud to have developed an alternative to natural aggregates in road construction, and ably demonstrated that roads made using steel slag can work. We are thrilled to be receiving this recognition from the India Book of Records. We are confident that steel slag will become a popular raw material in road construction in the coming years,” said Dr Anil Matoo, Head HR Operations, IR, and Administration at AM/NS India.

In fact, AM/NS India has already started receiving orders for steel slag for the construction of highways. In June, AM/NS India won the order for the supply of 1 lakh tonnes of steel slag for the construction of a 36.93 km eight-lane stretch from Ena to Kim in Surat as a part of the upcoming Vadodara-Mumbai Expressway.

Steel slag offers several benefits over natural aggregates. It is an ideal aggregate material due to its good shape factor, high abrasion resistance, and excellent skid resistance properties. It also has a higher load-bearing capacity compared to natural aggregates, making it more durable. Moreover, slag is readily available in bulk quantity.